Critical Spare Parts Management for Industrial Gearboxes

- Dec 15, 2025

- 2 min read

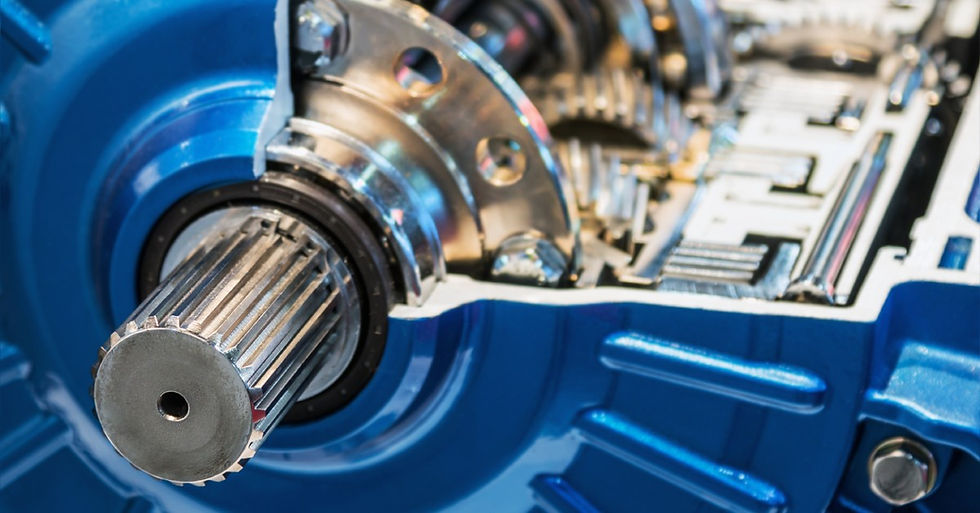

Industrial gearboxes serve as the backbone of manufacturing and processing facilities. These robust machines handle immense loads and transmit power essential for daily operations. When a gearbox fails, the entire production line often grinds to a halt, costing the company valuable time and revenue. Maximizing uptime requires more than just reactive repairs; you need a strategic approach to spare parts management. Keep reading to explore critical spare parts management for industrial gearboxes.

Identifying Critical Spare Parts

Identifying which components demand immediate availability constitutes the first step in a solid management plan. Bearings and seals typically wear out faster than other components due to friction and heat generation. Keeping a stock of these consumable items prevents minor issues from escalating into catastrophic failures.

Gears and pinions also endure significant stress. While they might last longer than seals, their failure results in extended downtime if replacements remain unavailable. You should also consider housing components and shims, as these parts often require replacement during a comprehensive rebuild.

Inventory Management Strategies

Effective inventory management requires balancing the cost of stocking parts against the cost of downtime. You cannot feasibly stock every single component for every machine. Instead, prioritize parts based on their lead times and criticality. If a specialized gear requires an eight-week lead time from the manufacturer, keeping one on the shelf makes financial sense.

Utilize inventory tracking software to monitor usage rates and set automatic reorder points. Strong relationships with suppliers also play a vital role. A reliable partner can expedite delivery in emergencies.

Benefits of Proper Management

Proper spare parts management directly impacts the bottom line. Immediate access to critical components reduces the mean time to repair (MTTR), allowing operations to resume quickly. This efficiency eliminates the need for expensive rush shipping and emergency fabrication costs.

A well-organized inventory empowers maintenance teams to perform scheduled preventive maintenance without delays, thereby extending the equipment’s overall lifespan. For facilities seeking expert gearbox repair in the Midwest, a well-maintained spare parts inventory complements professional service by speeding up the refurbishment process.

Taking a Proactive Approach

Industrial operations depend on the reliability of their machinery. A proactive approach to spare parts management protects that reliability. By identifying critical components, organizing inventory effectively, and understanding the financial benefits, facility managers safeguard their productivity. Do not wait for a breakdown to discover you lack a crucial bearing. Start assessing your inventory needs today and build a safety net for your operations.

Comments